Tooling

As a Professional Engineer (P.Eng.), Michael Hartley has the skillset to develop his own tools. But it’s more than training and education, for Michael it’s hard-wired into his being, beginning with his first bike work stand, built in 1972, through to his unique spoke tool, to the simple yet precise wheel lacing stand he uses today. Actually, he still uses that original bike work stand too. Built well once is all that’s needed.

From time to time we’ll be sharing some of Michael’s more innovative tooling designs here on the website, in Michael’s own words.

Bike Work Stand

“My bike stand dates from 1972. It was my very first piece of engineered tooling. One commentator said it looked ‘rat rod’. It may look ‘rat rod’ perhaps crude, but it contains some very unique features:

1. it controls the bike to eight degrees of freedom

2. it incorporates an interchangeable tool head

3. it’s easy to adjust

4. it was built from ‘off-the-shelf’ components and locally sourced materials

5. it was manufactured locally, in the machine shop owned by the father of someone in my high school.

Not bad for a 15-year old who had not the slightest idea what ‘engineering’ was. I still regularly use it in my shop.”

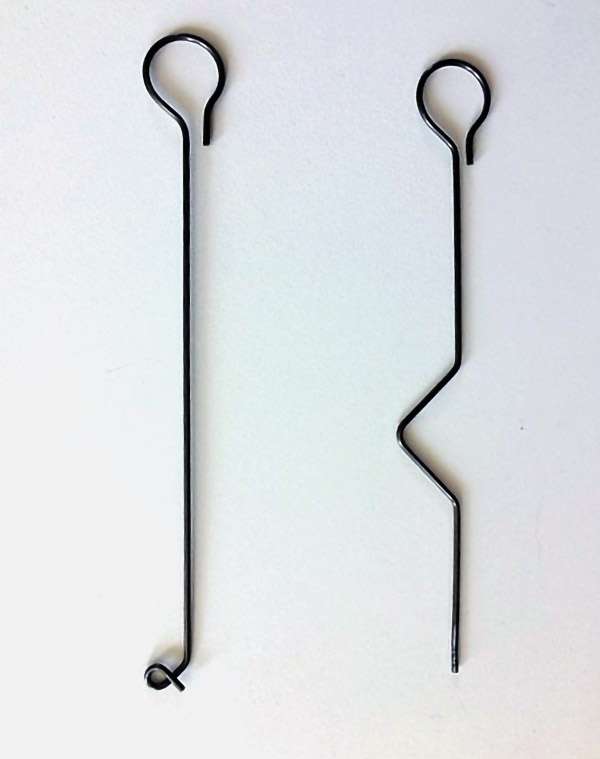

Designed in-house and built in a local spring manufacturing facility.

Michael’s spoke tool in action!

Bespoke Spoke Tools

“The reason why these tools were invented is why every wheel builder, in my opinion, must have them: they prevent nipples from being dropped inside box-profile rims, improving building efficiency and operating margin. It’s an old adage in the life of an inventor that, as you know, an inventor should never fall in love with his or her ideas, but, to tell the truth, these tools work damn well: in the eight years since inventing them, I’ve never lost a nipple inside a rim, and just that saving in time alone has more than paid for not only the cost of making the tool prototypes but delivered a healthy return. The development program of these tools followed the familiar pattern: designed in-house and built in a local spring manufacturing facility (there are quite a few spring manufacturers in the GTA!).

One of the reasons why, I think, these tools never sold is because, at least to a mechanic, they look like they are made out of spoke wire (most mechanics, including yours truly, would rather attempt to make their own out of spoke wire than purchase them). In fact, they are made of piano wire. They can be flexed, like any wire, but they cannot be ‘bent’ (plastically deformed) unless coined with a hammer, because piano wire has a yield strength of about 270,000 psi (!), rendering these tools totally beyond any human capability to induce a plastic set. Frankly, at CDN$25.00 a pair, they’re a bargain because of their exceptional strength and durability.”

Wheel Lacing Stand

“This tool was engineered and designed by yours truly over a six-year period and manufactured in a local machine shop. I took delivery of it in April 2025. It uses ‘industrial strength’ sections and materials.

I designed all the components, including the capstan bearings (enclosed in the blue caps), except the fasteners and extruded T-slots, and I commissioned a local machine shop to build it. It accomodates a wide range of axle diameters, hub and rims widths, and options for mounting tooling.”